Transformer Management & Control

SIGMA-Simulation On-Line Monitoring Sub-System Temperature Forecasting Simulation

One of the principal factors limiting the loading of power transformers is the temperature attained by the equipment, as a result of its loading and the ambient conditions. High operational temperatures, while accelerating the loss of insulation life can increase the risk of failures (for example, the risk of bubble formation). SIGMA Simulation is a…

Smart Trafo

Capture of information and readings on substation equipment, such as power transformers, began with electro-mechanical devices and handwritten notes made by operators, later evolving to electronic equipment with analog transmission of readings. Currently, with the widespread use of micro-controllers, microprocessors and computers, digitized information has become the most efficient and economical manner of capturing data…

SIGMA – Hydro On-line Monitoring Sub-system Oil and Solid Insulation Humidity

The presence of an excess water in a power transformer’s insulation system, in either the oil or solid insulation, causes diverse well-known negative effects. These including the lowering of the dielectric rigidity at low temperatures and the migration of water to and from the insulation paper, with the risk of bubble formation and rapid ageing…

SIGMA – LTC Assist On-line Monitoring Sub-system Maintenance Assistant for On-load Tap Changer

The Load Tap Changer (LTC) is one of the principal sources of failures in power transformers, due to the presence of moving parts that conduct and interrupt high currents while exposed to high electrical potentials. For this reason, as well as failures of a thermal and mechanical nature (see SIGMA LTC Diff and SIGMA LTC…

SIGMA – LTC Diff On-line Monitoring Sub-system Load Tap Changer Temperature Differential

The Load Tap Changer (LTC) is one of the principal sources of failure in power transformers, arising from the moving parts that conduct and interrupt high currents while exposed to high electrical potentials. The most common of these tap changer modes of failure are related to the contact deterioration or mechanical wear and tear that…

SIGMA – LTC Torque On-line Monitoring Sub-system Load Tap Changer Motor Torque

The Load Tap Changer (LTC) is one of the principal sources of failures in power transformers, arising from the existence of moving parts that conduct and interrupt high currents while exposed to high electrical potentials. As well as thermal failures (see SIGMA LTC Diff Sub-system), some of the common failure modes in LTCs are of…

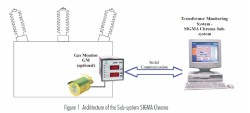

SIGMA – Chroma On-line Monitoring Sub-system Dissolved Hydrogen, Chromatographic and Physical-chemical Tests

Gases dissolved in oil is recognized as one of the best indicators of the internal condition of transformers and reactors, and the analysis of the gas content of oil was largely propagated as a diagnostic tool for this equipment. This resulted in the development of a broad knowledge base and diverse techniques, to analyse the…

SIGMA – Efficiency On-line Monitoring Sub-system Cooling System Efficiency

Appropriate cooling of a transformer is fundamental for its safe operation to prevent the acceleration in the loss of useful insulation life, in the presence of high loading. Therefore, it is essential that the natural and forced cooling equipment, such as radiators, fans and oil pumps, should be in perfect working order, efficiently dissipating heat…

SIGMA – Fan On-line Monitoring Sub-system Assistant for Maintenance of the Cooling System

Adequate cooling of a transformer is fundamental for its safe operation and the prevention of accelerated aging and reduction in the useful insulation life under high loading. Thus, it is essential that the forced cooling equipment, such as fans and oil pumps, function perfectly. The total or partial failure of the cooling equipment can activate…